What is the difference between standard stone wool and lamella passive fire protection solutions?

There are several different types of cavity barrier, firestop and perimeter seal solutions on the market developed for different façade types. These include curtain walling, rainscreen and composite cladding systems, precast concrete façades, and masonry walls. In all applications, it is vital that the chosen solution not only delivers the required fire resistance but also maintains the right level of compressibility and fit within the given void width for the lifetime of the system, even when subjected to building movement. Therefore, the durability and orientation of the stone wool fibres within the product is a key element in this functional performance.

Horizontal-fibred stone wool solutions

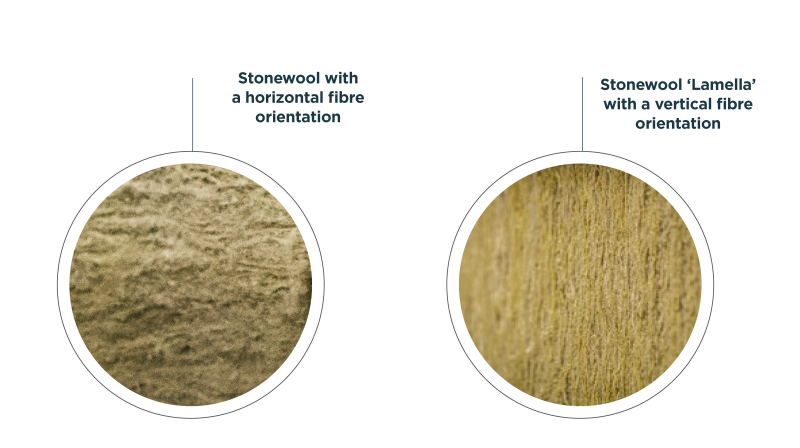

Standard passive fire protection products typically use non-combustible stone wool insulation with a horizontal fibre orientation. This makes the products stable but can equally make them resistant to lateral compression (across their width).

Continual exposure to movement and compression can result in breakdown of the bonding between the fibres, essentially ‘crushing’ them. This means that the product will not recover / flex in line with how the façade, inner leaf or floor slab is moving, which can result in a gap forming between the product and the façade over time, potentially causing the compartmentation provided by the cavity barrier, firestop or perimeter seal to fail prematurely.

In curtain wall applications, they also often require a ‘wet’ install, where installers cut and compress the insulation material onsite before sealing it with a sprayed-on compound. Once applied and cured, the only way to truly check the right compression has been achieved is through post-installation destructive testing.

Lamella (vertical-fibred) stone wool solutions

In response to the limitations presented by horizontally fibred products, Lamella products were engineered by us, here at Siderise. These feature a special formulation stone wool insulation with vertically oriented fibres, which are laterally compressed under quality-controlled factory conditions using a unique manufacturing process to assist with uniformity of product density, and remove any gaps between the adjoining cut sections, which may result in weakness.

This ‘pre-compression’ is held in place by heat-applying a foil facing to the cut face of the fibres, which also provides weather protection without the need for a wet sealant. When exposed to fire, this foil facing is sacrificed from the Lamella core, releasing the factory-induced compression. This allows the fibres to expand and ensure integrity is maintained - even under the movement caused by the fire load.

This unique and robust composition enables Lamella solutions to simply be friction fitted or installed with further compression of 10%, 20%, 5mm or 10mm with or without steel brackets, depending on factors such as the void width and façade type. What’s more, this additional compression wrinkles the foil, making it very easy to confirm if the product has been installed correctly without the need for destructive testing, unlike ‘wet-fit’ solutions.

As accelerated age testing in accordance with EOTA Technical Report 024 demonstrates, the Siderise vertical fibre structure allows our products to be repeatedly laterally compressed with no loss of recovery / flex. This gives them the ability to accommodate in-service movement, allowing the integrity of seal between the façade and floor slab / inner leaf to be constantly maintained for the lifetime of the building.

Robust options for long lasting building safety

Due to its resilient nature and practicality on site, Lamella now features in many of our passive fire protection and acoustic product ranges and has been used on projects around the world. Nonetheless, whichever solution is chosen, it is always important to ensure that the products have been thoroughly tested to standards relevant to their intended application and can demonstrate their suitability for that application.

Explore our passive fire protection products or check out our project case studies to learn more.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response