Siderise EW Closed State Cavity Barrier and Firestop

Cavity barriers and firestops to protect compartment lines and around openings in masonry walls

Closed state cavity barrier and firestop

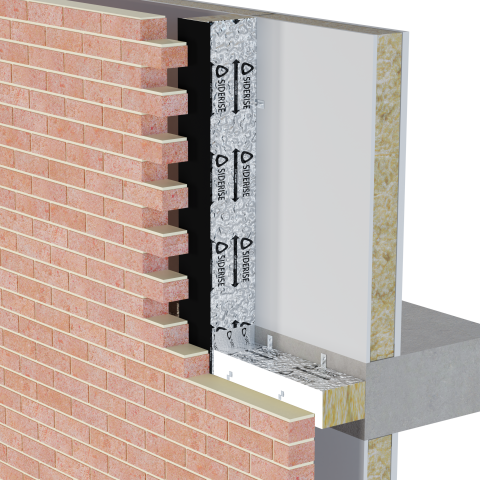

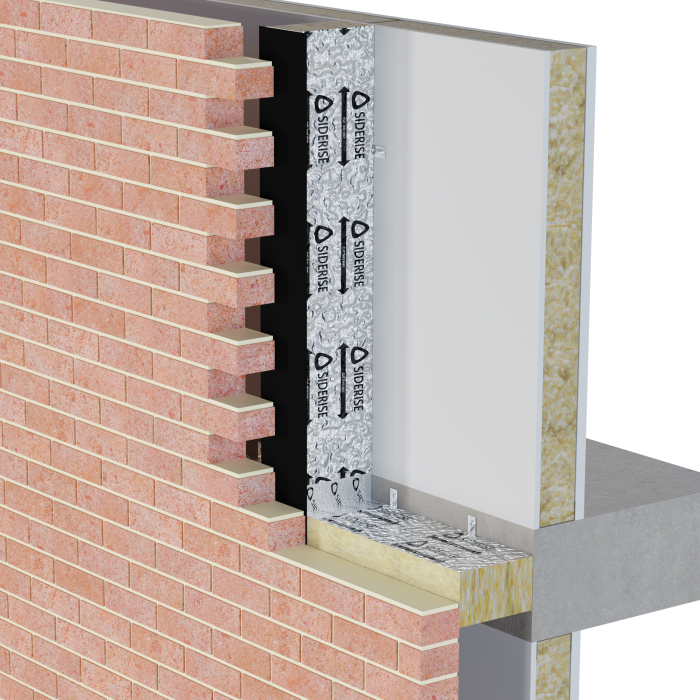

EW Cavity Barrier and Firestop provides compartmentation in external masonry walls, with friction fit options for the entire product range available for cavities up to 400mm. The product features a Lamella insulation core comprising durable vertically oriented stone wool fibres compressed under factory-controlled conditions and held in place with aluminium foil facings heat-bonded to the cut face of the fibres. Lamella is key to accommodating site tolerances and localised common imperfections in brickwork.

The product installation requires fixing brackets and jointing tape all supplied by Siderise as part of a complete package. Friction fit options for the entire product range, both horizontal and vertical, and void range, 20-400mm voids, means products do not need to be installed with compression and can be applied to wet brickwork without compromising the stability of the wall structure.

The stone wool Lamella composition allows EW Cavity Barrier and Firestop to be effortlessly notched. This means components commonly interrupting the firestopping line e.g. masonry support brackets, can be easily accommodated

Tested to BS EN1366-4:2006+A1:2010 and BS EN 1366-4:2021 with third-party certification through IFCC 1830, which covers both horizontal and vertical applications and incorporates fixing brackets and aluminium foil jointing tape

EW Closed State Cavity Barrier and Firestops products have achieved CCPI assessed status (Applies to EW-CB30, EW-FS60 & EW-FS120 only). This provides greater confidence that the product information we publish about these products is clear, accurate, up-to-date, accessible, and unambiguous — and is checked and managed by competent people

To suit specific cavity barrier and firestop specification requirements, EW Cavity Barrier and Firestop is available with fire resistance performance ratings ranging from 30mins to 120 mins for 20-400mm voids both horizontally and vertically.

To demonstrate compatibility and provide assurance that performance is not compromised, EW Cavity Barrier and Firestop incorporating DPCs has been tested to BS EN 1366-4:2021, and EW-FS120 has been tested with masonry support angles with differing levels of penetrations

External masonry wall cavity barrier and firestop systems

Closed state fire protection solutions for masonry constructions

Siderise EW Systems have been developed to provide a tested method of sealing external wall cavities to provide resistance to the passage of fire in external masonry constructions.

The EW product range is for use as a Cavity Barrier or Firestop in accordance with the guidance supporting the national Building Regulations.

Friction fit installation is available throughout the range to support installation with ‘green’ brickwork, which brings considerable advantages to the construction timeline.

In addition to providing an effective seal against the passage of fire, the products are also acoustically absorptive.

These products represent an ideal combination of fully qualified performance and practical installation. 3rd party product approval is provided by IFC Certification (IFCC 1830).

CCPI assessed status

EW Closed State Cavity Barrier and Firestops products have been assessed under the CCPI scheme.

Assessment Number: 000800104/1126

Siderise EW systems are manufactured using a unique method that provides resilient lateral compression. This facilitates installation, ensuring the requisite tight fit and enhancing the fire integrity of the product.

Throughout the range, the materials comprise a one-piece product with a pre-compressed non-combustible stone wool core. The products also have integral aluminium foil facings to provide an overall Class A1 rating (To BS EN 13501-1:2018).

Available in the following forms:

Pre-cut Strips

- Pre-cut products are available in 1mm increments of width to suit the cavity size.

- Supplied with appropriate brackets when part of the system.

Sheets

- Standard sheet size is 1200 x 1200mm and may be of benefit when the actual void size is not known or to accommodate site tolerance (where the void may vary significantly).

- Appropriate brackets must be ordered separately.

Siderise EW should be installed in accordance with PD6697:2019 - 'Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2'.

- Horizontal - EW must be installed with a suitable cavity tray located above.

- Vertical - EW must be installed with a DPC extending a minimum of 25mm into the cavity on either side. DPC to be sourced separately. If requested by Building Control / Warranty provider the DPC can be optionally secured with Siderise RFT 120/45 foil tape.

Reaction to Fire

This is the response of a material in contributing by its own decomposition to a fire to which it is exposed under specified conditions. Results are classified to BS EN 13501-1:2018 “Fire classification of construction products and building elements”.

Siderise EW Systems are classified as A1 to BS EN 13501-1:2018. This is detailed further in Third-party certification with Intertek. Please see Table 1 for further information.

Table 1: Reaction to Fire Performance

| Properties | Value |

|---|---|

| Classification |

A1 to BS EN 13501-1: 2018 |

| Certificate No. |

WHI-09/02-22-000001-03 (UK) WHI20-32944302 (US) |

| Thickness Range |

50-175mm* |

| Substrates |

Mechanically fixed to gypsum or any other A1 or A2-s1, d0 substrate |

| Joints |

With or without joints |

*Please note that the thickness declared here refers to reaction to fire testing (supported by certificates - WHI-09/02-22-000001-03 (UK) & WHI20-32944302 (US)) carried out on the base material from which EW is manufactured and so covers a wider range than the thicknesses used for EW resistance to fire testing shown in table 2 and 3.

Resistance to Fire

This is the ability of an element of structure or product to maintain its stability for a specific period as determined by the loadbearing capacity (for structural elements only), integrity and/or insulation against heat transfer specified in the fire resistance test. Results are given in accordance with BS EN 13501-2:2023.

Siderise EW Systems have been tested in accordance with BS EN1366-4:2006 + A1:2010 and BS EN 1366-4: 2021(Only applies to EW-FS60 for horizontal voids 51-250mm, EW-FS60 for vertical voids 251-400mm and EW-FS120 horizontal voids with MSA – 250mm).

Siderise EW Systems maintained integrity (E) and insulation (I) requirements as detailed in Tables 2-3. 3rd party product approval is provided by IFC Certification (IFCC 1830).

Table 2: Resistance to Fire to EN1366-4:2006+A1:2010 & *BS EN1366-4: 2021 (Horizontal or Vertical)

| Product Ref | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Mins) | Insulation (mins) | Product Length (mm) | Bracket Requirement | Third-party Certification |

|---|---|---|---|---|---|---|---|---|

|

EW-CB30 |

20 - 50 |

75 |

Friction |

90 |

30 |

1200 |

None. |

IFCC 1830 |

|

51 - 150 |

75 |

Friction |

90 |

30 |

1200 |

2no.B65/110 600mm centres |

IFCC 1830 |

|

|

151 - 250 |

75 |

Friction |

90 |

30 |

1200 |

2no.B195 600mm centres |

IFCC 1830 |

|

|

EW-CB30X |

251 - 400 |

90 |

Friction |

90 |

30 |

1200 |

2no.B355 600mm centres |

IFCC 1830 |

|

EW-FS60 |

20 - 50 |

100 |

Friction |

90 |

60 |

1200 |

None. |

IFCC 1830 |

|

51 - 150 |

100 |

Friction |

90 |

60 |

1200 |

2no.B65/110 600mm centres |

IFCC 1830 |

|

|

151 - 250 |

90 |

Friction |

90 |

60 |

1200 |

2no.B195 600mm centres |

IFCC 1830 |

|

|

EW-FS60X |

251 - 400 |

120 |

Friction |

90 |

60 |

1200 |

2no.B355 600mm centres |

IFCC 1830 |

|

EW-FS120 |

20 - 50 |

120 |

Friction |

120 |

120 |

1200 |

None. |

IFCC 1830 |

|

51 - 150 |

120 |

Friction |

120 |

120 |

1200 |

2no.B65/110 600mm centres |

IFCC 1830 |

|

|

151 - 250 |

120 |

Friction |

120 |

120 |

1200 |

2no.B195 600mm centres |

IFCC 1830 |

|

|

EW-FS120X |

251 - 400 |

150 |

Friction |

120 |

120 |

1200 |

2no.B355 600mm centres |

IFCC 1830 |

* BS EN 1366-4: 2021(Only applies to EW-FS60 for horizontal voids 51-250mm, EW-FS60 for vertical voids 251-400mm and EW-FS120 horizontal voids with MSA – 250mm).

Table 3: Resistance to Fire to EN1366-4:2021 (Horizontal with Masonry Support Angle Interface)

| Product Ref | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Mins) | Insulation (mins) | Product Length (mm) | Bracket Requirement | Third-party Certification |

|---|---|---|---|---|---|---|---|---|

|

EW-FS120 with MSA*(1) |

250 (Tested) |

120 |

Friction |

120 |

120 |

1200 |

2no.B355 600mm centres |

IFCC 1830 |

|

EW-FS120 with MSA*(2) |

250 (Tested) |

120 |

Friction |

120 |

120 |

1200 |

2no.B355 600mm centres |

IFCC 1830 |

|

EW-FS120 with MSA*(3) |

250 (Tested) |

120 |

Friction |

120 |

120 |

1200 |

2no.B355 600mm centres |

IFCC 1830 |

*Siderise has undertaken additional testing with EW-FS120 which includes masonry support angles (MSA) penetrating the system. For more information on these tests please refer to IFCC 1830 or contact technical.services@siderise.com

(1) In this test specimen the MSA penetrates the product and protrudes from the unexposed face by 18mm

(2) In this test specimen the MSA penetrates the product and is finished flush with the unexposed face and protrudes the exposed face by 15mm

(3) In this test specimen the MSA penetrates the product by 50% and protrudes the exposed face by 75mm

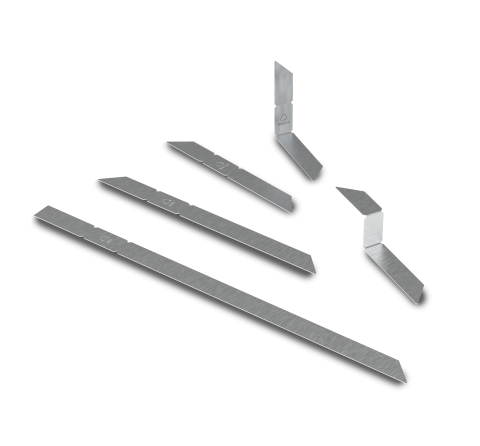

- All brackets are to be suitably fixed to the substrate with non-combustible fixings, or mortared into masonry coursing.

- All brackets to penetrate product at mid-thickness.

- All brackets to penetrate to a depth of 75% of gap width.

- Brackets are available in two forms: (G) denotes galvanised steel brackets and (S) denotes stainless steel brackets.

- Brackets must be installed at 600mm centres based on a 1200mm strip. This can be reduced pro rata for shorter lengths. Please note that 2 brackets are required for any length of barrier greater than 250mm. For lengths ≤250mm a single bracket can be utilised.

- Whilst the EW range has been tested in general accordance with BS EN 1366-4:2006+A1:2010 “Fire resistance tests for service installations - Linear joint seals.” without mechanical fixings and brackets, we note that some supervising authorities may require a form of mechanical fixing. We recommend engaging with the project supervising authorities prior to installation to ensure all their requirements are met.

Friction Fit - product should be sized equal to the void width and installed with no gaps.

Compression Fit - the product should be sized to the void width plus a minimum of +10mm or 10% compression (Please see Tables 2 & 3). Care should be taken when installing under compression to ensure mortar has cured adequately to prevent deformation of the masonry outer leaf.

Please refer to the EW Installation Instructions (available for download from our website) for more information.

When considering Steel Frame Systems (SFS) the supporting substrate should be capable of providing support to the barrier for the required period of fire resistance. For other void sizes or additional advice, please contact Technical Support.

Due to the way cavity masonry façades typically interface with floor slabs it is not usual to rely on elements within the cavity to control flanking noise transfer between floors.

Flanking performance for masonry façades is typically controlled by internal finishes such as high mass plasterboard linings.

Table 4 confirms the laboratory tested values for Weighted Sound Reduction Index (dB Rw) in accordance BS EN ISO 10140-2:2021; Acoustics-Laboratory measurement of sound insulation of building elements, Part 2: Measurement of airborne sound insulation.

Table 4: EW Acoustic Performance - Weighted Sound Reduction Index

| Product Type | Thickness (mm) | Rw (dB) | C:Ctr |

|---|---|---|---|

|

EW-CB30 |

75 |

21 |

(-1;-2) |

|

CW-CB30X |

90 |

21 |

(-1;-2) |

|

EW-FS60 |

100 |

21 |

(-1;-2) |

|

EW-FS60X |

120 |

23 |

(-1;-3) |

|

EW-FS120 |

120 |

23 |

(-1;-3) |

|

EW-FS120X |

150 |

23 |

(-1;-3) |

An Rw is the weighted sound reduction index. It is a laboratory measured value to identify the airborne sound insulation performance of a building element. It is used for internal or external walls, ceilings/floors, windows, doors, or any separating element. The higher the Rw value, the better that element performs in reducing sound transmission.

Please note that the values presented in the above table refer to the standalone performance of the Siderise products only.

Please contact technical.services@siderise.com for project specific guidance relating to acoustic performance in masonry applications.

Thermal conductivity : λ = 0.038 W/m.K ±5% (tested foil to foil) to BS EN 12667: 2001

Damp Proofing

Siderise EW must be damp-proofed in accordance with PD6697:2019 - 'Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2'.

Siderise EW - Cavity Barriers and Fire Stops

Table 4: Product Properties

| Properties | Value |

|---|---|

| Form Supplied | Sheets: Standard sheet size is 1200 x 1200mm (UK), 1200mm x 1150mm (RoW): Thickness is denoted by the rating. Pre-cut strips: 1200mm length, width available in 1mm increments to suit the cavity size. Pre-cut strips are sized to allow for application of the relevant compression requirement (where applicable). |

| Reaction to Fire | Class 'A1' to BS EN 13501-1:2018 (see Table 1) |

| Resistance to Fire | 30 to 120 minutes(see Table 2 & 3) |

| Thermal Conductivity | λ = 0.038 W/m.K ±5% (tested foil to foil) to BS EN 12667: 2001 |

| Chemical | The base stone wool is chemically inert. An aqueous extract of the stone wool is neutral (pH7) or slightly alkaline. Resistant to most acids and weak alkaline solutions. |

| Biological | Vermin and rot proof and does not encourage the growth of fungi, moulds or bacteria. |

| Effect of water | Non-hygroscopic. Unaffected by humid atmosphere. Must be suitably damp proofed in accordance with codes of practice for masonry constructions |

| Compatibility | Compatible with all normal building materials. |

| Maintenance | No maintenance required unless disturbed. |

| Handling | See Material Data Sheet section 7. |

Siderise offers a range of ancillary products to complement the EW range these include:

Fixing Brackets must be used when required for the installation of the product.

Brackets come in two forms: 'G' - Galvanised Steel Brackets and 'S' - Stainless Steel Brackets.

Brackets are supplied with all EW in strip form, but must be ordered separately for all EW in sheet form.

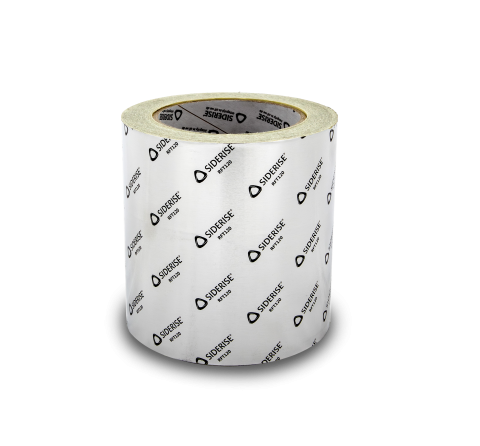

Aluminium Jointing Tape must be used at all joints and intersections:

- RFT120/45 (120mm wide x 45m rolls)

- Adhesive backed

- Supplied in boxes of 8

Table 5: Physical Characteristics

| Properties | Value |

|---|---|

| Manufacturer and Product Name | Siderise EW |

| Product Type | Cavity Barriers and Fire Stops for Masonry External Walls |

| Code/Model/Reference/SKU | EW |

| Description | See 'Product Description' section |

| Application/Use | See 'Application' section |

| Material | See Material Data Sheet section 3.1 |

| Weight | Precut strips - Max Carton Weight 30kg Full individual sheets from 8.3 +/- 0.1 kg to approx. 18.9+/- 0.4 kg (75mm to 150mm thick respectively) Based on Precut strips and Full sheets at 1200mm lengths. |

| Finish /Colour | Solid, green-brown exposed edges with silver aluminium top and bottom facings. |

| Packaging | Pre-cut strips packaged in cardboard cartons size; Full sheets packaged on pallets. |

| Pack Size | Pre-cut strips packaged in cardboard cartons size up to 1230mm x 610mm ; Max 8 cartons per pallet. Full sheets packaged on pallets 1210mm x 1210mm Packaged pallet max height approx. 2100mm. |

| Unit of measure | millimetre (mm) |

| Chemical properties/Safety data sheets | N/A |

| Size/dimensions (product & installation spatial requirement) | See Table 4 'Form Supplied' |

| Shelf life | n/a; Store in dry conditions and protect from mechanical damage. |

The stone wool core is recyclable.

The following information is available for download via the website:

- Third-party Certification - IFCC 1830

- Standard Details

- NBS Specification Clauses

- Installation Instructions

- Material Data Sheet

For technical advice or support please contact: technical.services@siderise.com

For Installation Training or Site Inspections please contact: site.services@siderise.com

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

Acoustic solutions

We have a range of acoustic treatments for buildings and construction sites.

Installation

View our installation video

FAQs

Get quick answers to common queries or contact our team for more advice. Your questions answered.

Yes, our site services engineers combine classroom learning with toolbox training and includes mock-up benchmark installations, free-of-charge.

Pre-cut products are available in 1mm increments of width to suit the cavity size. We can also supply standard 1200 x 1200mm sheets where the exact void is not known

Case Studies

Related projects

Siderise is a market leader in the design and development of specialist passive fire.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.