Siderise CH Horizontal Cavity Barrier

Horizontal full fill cavity barriers for non-ventilated cladding façade applications in regions with no moisture drainage requirements such as the Middle East, India and Asia Pacific

Full fill cavity fire protection

CH Horizontal Cavity Barrier is used to fully fill the void between the external envelope and internal structure in non-ventilated cladding systems used in climates where there is no need for moisture drainage. It is also ideal for maintaining ‘pressure-equalised’ compartmentation in some ventilated rainscreens. Its Lamella stone wool core features vertically oriented fibres that are laterally compressed and held in place by a foil facing. This creates a robust fire and smoke barrier that can withstand natural building movement typical in rainscreen façades for the lifetime of the structure.

Its pre-compressed, vertically fibred Lamella core allows CH Horizontal Cavity Barrier to accommodate the serviceability movement normally associated with rainscreen façades

CH Horizontal Cavity Barrier has been tested to EN 1366-4, with a range of insulation and integrity performance options to suit any project

The performance of CH Horizontal Cavity Barrier has been certified by Intertek US and UK (reaction to fire)

CH Horizontal Cavity Barrier has been used as part of a cladding system in multiple large-scale fire resistance tests, including BS 8414, NFPA 285

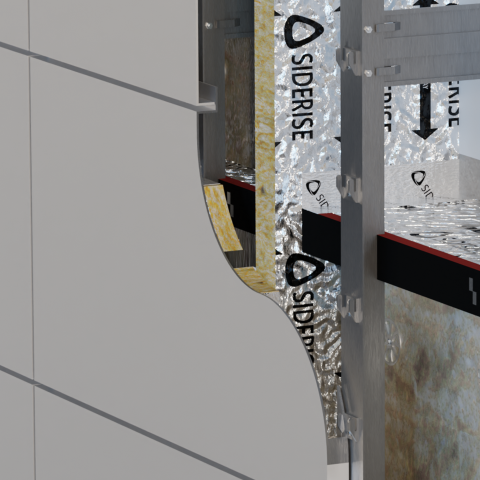

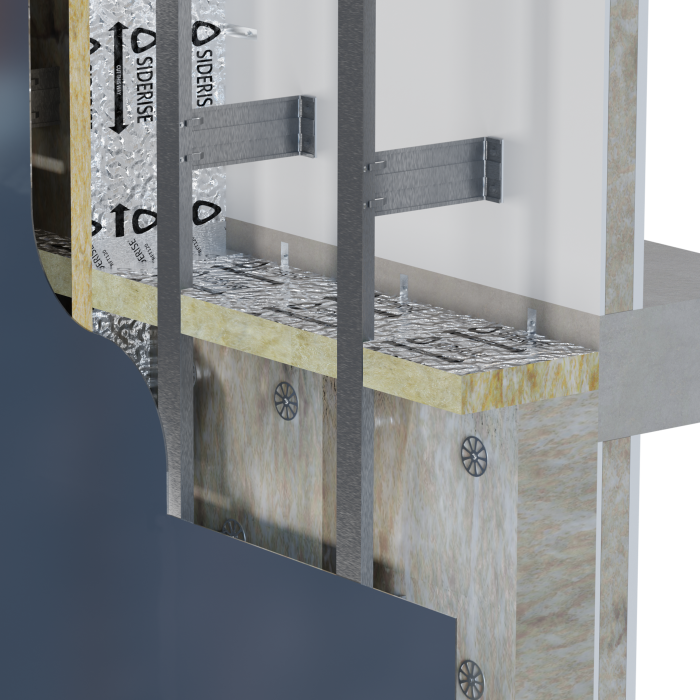

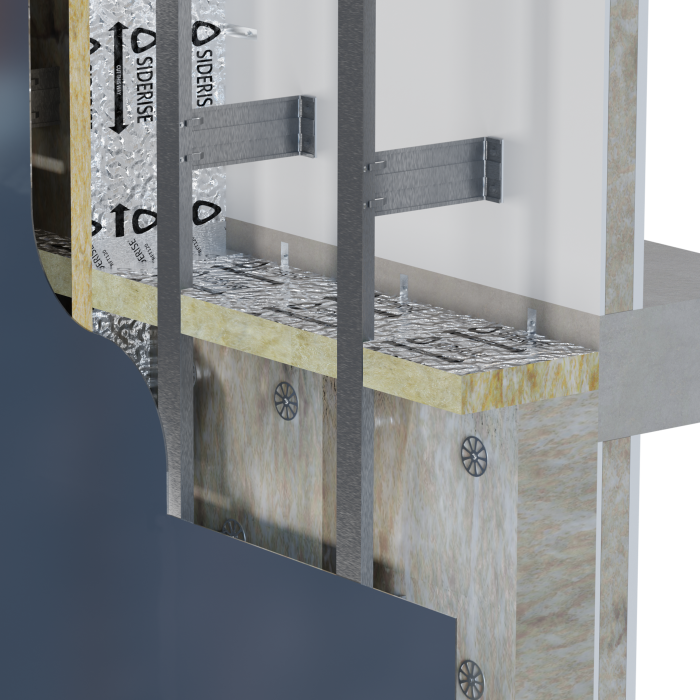

Siderise CH horizontal cavity barriers for non-ventilated cladding facades are used to full fill the void between the external envelope and internal structure. They are installed in combination with RV vertical cavity barriers as part of a system.

The construction of CH horizontal cavity barriers offers resistance to the passage of both smoke and fire. Additionally, by fully sealing the void, they assist ventilated façades to function by maintaining air pressurisation compartmentation.

Importantly, their unique pre-compressed stone wool lamella core construction enables the vertical barriers to accommodate the serviceability movement normally associated with rainscreen façades.

Intersections between horizontal and vertical cavity barriers are simply abutted. The leading edge compresses directly against the external envelope. No intumescent strip is required.

Siderise CH horizontal cavity barriers are installed within the cavity formed between the cladding facade and the inner structural wall using appropriate Siderise support brackets. Brackets are available in either galvanised mild steel (G) or stainless steel (S).

Siderise CH horizontal cavity barriers for rainscreen cladding applications consist of a non-combustible stone wool lamella core, with reinforced aluminium foil faces, giving an overall reaction to fire performance of Class ’A1’ to EN 13501-1.

Standard sheet sizes are 1200mm x 1150mm.

Product Fire Performance

Siderise CH horizontal cavity barriers have been tested in accordance with EN 1366-4: 2006+A1: 2010. The cavity barriers maintained integrity (E) and insulation (I) requirements for up to 2 hours as detailed in Table 1.

The tests have been undertaken to assess the ability of the cavity barriers to reinstate the fire resistance of a lightweight aerated concrete supporting construction. This is the standard assembly for testing such cavity barrier products as it allows the performance of the individual barrier to be classified.

System Fire Performance

Siderise cavity barrier products have been used in a growing number of large-scale system tests such as BS 8414 (1&2) and NFPA 285. These may be used to evaluate the performance of the Siderise cavity barriers within a complete cladding system. The rules for extended application of results from BS 8414 tests are subsequently defined in BS 9414.

In all cases, we recommend that the specifier and user review the specific project configuration regarding available large-scale system test data and the latest National Building Regulations, local Building Code and/or government advice.

For information regarding performance and assembly details in system tests please contact the technical team.

Table 1: Fire Resistance to EN 1366-4

| Product Ref | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Mins) | Insulation (mins) | Product Length (mm) | Bracket Requirement |

|---|---|---|---|---|---|---|---|

|

CH-30/30 |

20 - 50 |

75 |

+5mm |

60 |

30 |

1200 |

None. |

|

CH-60/60 |

20 - 50 |

90 |

+5mm |

90 |

60 |

1200 |

None. |

|

CH-120/120 |

20 - 50 |

120 |

+5mm |

120 |

120 |

1200 |

None. |

|

CH-30/30 |

51 - 150 |

75 |

+10mm |

60 |

30 |

1200 |

2no. B65/110 |

|

CH-60/60 |

51 - 150 |

90 |

+10mm |

90 |

60 |

1200 |

2no. B65/110 |

|

CH-120/120 |

51 - 150 |

120 |

+10mm |

120 |

120 |

1200 |

2no. B65/110 |

|

CH-30/30 |

151 - 250 |

75 |

+10mm |

60 |

30 |

1200 |

2no. B195 |

|

CH-60/60 |

151 - 250 |

90 |

+10mm |

90 |

60 |

1200 |

2no. B195 |

|

CH-120/120 |

151 - 250 |

120 |

+10mm |

120 |

120 |

1200 |

2no. B195 |

|

CH-30/30 |

251 - 300 |

75 |

+10mm |

60 |

30 |

1200 |

2no. B355 |

|

CH-60/60 |

251 - 300 |

90 |

+10mm |

90 |

60 |

1200 |

2no. B355 |

|

CH-120/120 |

251 - 300 |

120 |

+10mm |

120 |

120 |

1200 |

2no. B355 |

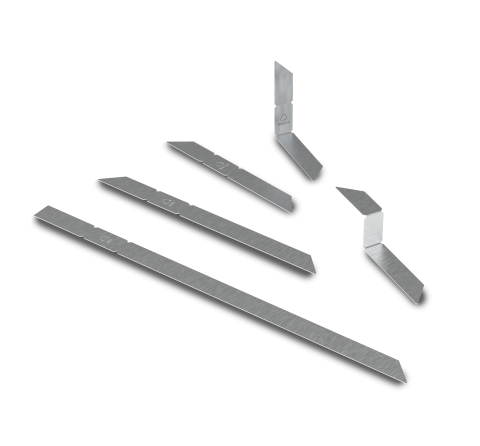

Please note:

- Support brackets should be installed at 600mm fixing centres (300mm from each end).

- The brackets are supplied as standard in 1mm galvanised mild steel (G) or stainless steel (S), in a flat form for site folding.

- Lengths of the barrier are secured with these dedicated brackets, which impale the product at mid-thickness to a depth of 75% of void.

- The brackets are secured to the inner structural wall using non-combustible steel anchors or screws. These fixings are not supplied by Siderise.

- Please see separate installation instructions available on our website.

Thermal conductivity: λ= 0.038 W/m.K (tested foil to foil)

Table 2: Product Properties

| Properties | Value |

|---|---|

| Form Supplied |

Sheets : 1200mm x 1200mm (UK and EU); 1200mm x 1150mm (RoW): Thickness is denoted by the rating Pre-cut strips : 1200mm x (cavity + compression) x thickness, please see Tables 1 |

| Product Finish |

Aluminium foil to surfaces exposed to cavity |

| Density |

Nominal 75 kg/m3 |

| Thermal Conductivity |

λ = 0.038 W/m.K (tested foil to foil) |

| Void Sizes |

20mm to 300mm - please see table 1 |

| Reaction to Fire |

Classified A1 to EN 13501-1 |

| Resistance to Fire |

Please see Table 1 CH-30/30 cavity barriers are manufactured from CW-CB30 CH-60/60 cavity barriers are manufactured from CW-FS60 CH-120/120 cavity barriers are manufactured from CW-FS120 CW-FS is certified under Certifire CF 563 and Intertek WHI19-32944301. |

Stone wool core is recyclable

The following information is available upon request or via download from the website:

- Standard Details

- Material Data Sheet

- Installation Instructions

Technical Services Team: technical.services@siderise.com

For Installation Training or Site Inspections please contact: site.services@siderise.com

For technical advice or support in the Middle East, India or Asia Pacific contact: smetech@siderise.com

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

Products

Related products

Siderise products developed to meet the unique demands of cladding façades

Acoustic solutions

We have a range of acoustic treatments for buildings and construction sites.

Test data

View our testing data and see how we can help you go beyond on your next façade project

Products

Related products

Passive fire protection products designed to work holistically

FAQs

Get quick answers to common queries or contact our team for more advice. Your questions answered.

Yes, our site services engineers combine classroom learning with toolbox training and includes mock-up benchmark installations, free-of-charge.

Yes, brackets are available in two forms: galvanised steel brackets (G) and denotes stainless steel brackets (S). These are supplied in a flat form with pre-notched indents for site folding

Yes, we have participated in a significant number of large-scale system tests (including BS 8414, NFPA 285). Please see our database of large scale testing for more information

Yes, CH Horizontal Cavity Barrier is suitable for use with our RV Vertical Cavity Barrier. Please see our Siderise CH/RV Closed State Cavity Barrier Systems for non-ventilated cladding

Siderise created Lamella insulation in the 1990s to provide a fire resistant core that could also withstand building movement for reliable form and fit

Case Studies

Related projects

Siderise is a market leader in the design and development of specialist passive fire

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.