Siderise EWI Open State Cavity Barrier and Firestop

A horizontal fire and smoke barrier with integral intumescent to protect irregular cavities in masonry walls

Open state cavity barrier and firestop

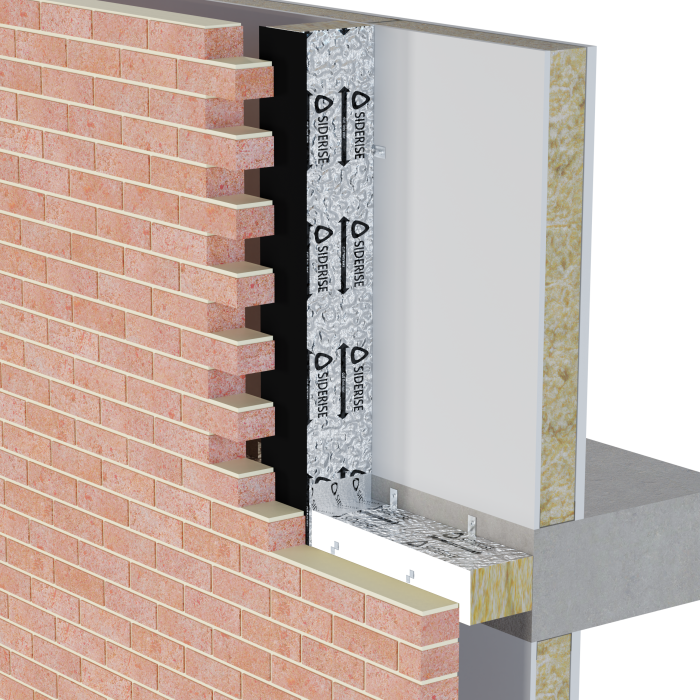

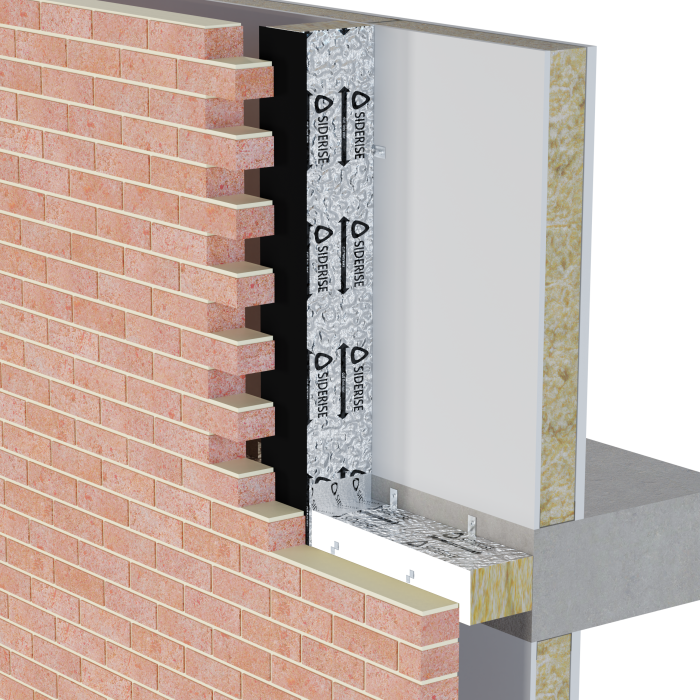

EWI is a horizontal cavity barrier and firestop solution developed to seal inconsistent cavities between external masonry façades and either a SFS or a blockwork inner leaf. The products feature a pre-compressed, vertically fibred Lamella stone wool insulation core sealed with a reinforced aluminium foil, with an integral intumescent strip on the leading edge. In the event of fire, this rapidly expands to meet and mould to the face of the outer construction, forming a robust seal.

EWI Cavity Barrier and Firestop has been tested for cavity widths up to 350mm in a horizontal application allowing for air gaps up to 25mm.

EWI Cavity Barrier and Firestop has been tested in accordance with ASFP Technical Guidance Document (TGD) 19 Fire resistance test for 'open-state' cavity barriers used in the external envelope or fabric of buildings.

The integral intumescent in the EWI Cavity Barrier and Firestop allows irregular cavity depths caused by decorative offset brickwork to be effectively protected, with no need to try and accurately notch standard cavity barriers onsite.

This horizontal cavity barrier and firestop solution should be installed in conjunction with EW Cavity Barrier and Firestop for vertical applications.

External masonry wall cavity barrier and firestop systems

Closed state fire protection solutions for masonry constructions

Siderise EWI Systems have been specially developed via the incorporation of an integral intumescent, which in the event of a fire, provides a reactive method of sealing masonry wall cavities that have an irregular inner face to the outer masonry leaf such as decorative features.

Siderise EWI systems are currently available for horizontal applications as Cavity Barriers or Firestops (dependent on application) in accordance with the guidance supporting the national Building Regulations, with the product codes as listed below:

- EW25-CB30

- EW25-FS120

These products represent an ideal combination of fully qualified performance and practical installation.

Where there is a vertical cavity barrier requirement, our Siderise EW vertical full fill barriers should be used in conjunction with the EWI horizontal open-state barriers in masonry wall applications.

The suitability of this product should be checked with the relevant building control and warranty provider for the project.

Siderise EWI Systems comprise of a low resin content stone wool insulation core which is pre-compressed internally to form a resilient strip. The material is faced on two sides with a reinforced aluminium foil which provides an effective smoke barrier once the product has activated and fully sealed the void. Siderise EWI incorporates an integral reactive intumescent. The leading edge is encapsulated in a white weather-resistant polymer film.

Siderise EWI is only supplied in pre-cut strips:

- Pre-cut products are available in 1mm increments of width to suit the cavity size. Please see Table 1.

- Supplied with appropriate brackets as part of a system (see Table 1).

Siderise EWI should be installed in accordance with PD6697:2019 - 'Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2'.

If Siderise EWI is in contact with the outer masonry (thereby bridging the cavity), it must be installed with a Cavity Tray directly above. Where there is no contact with the outer masonry leaf (i.e. a continuous uninterrupted air gap) a cavity tray may no longer

be required depending on the specific project requirements, except where otherwise called for such as above openings. Please refer to 3rd party warranty providers, such as NHBC, LABC and Premier Guarantee for further guidance.

Siderise EWI systems have been tested in accordance with TGD 19 Fire resistance test for 'open-state' cavity barriers used in the external envelope or fabric of buildings.

- Resistance to Fire - is expressed as Integrity (E) and Insulation (I) performance in minutes, please see Table 1.

- Reaction to Fire - Classification to EN 13501-1 : 'A1' (core), 'E' (intumescent) as permitted by Regulation 7(3).

Table 1 : Fire Resistance to ‘General Principles of ASFP - TGD 19’ (Horizontal Orientation)

| Product Ref | Thickness (mm) | Void Range (mm) | Air Gap (mm)** | Bracket Requirement | Integrity (Mins) | Insulation (mins) |

|---|---|---|---|---|---|---|

|

EW25-CB30 |

75 |

76 - 250 |

≤ 25 |

RS 350 |

90 |

30 |

|

75 |

251 - 350 |

≤ 25 |

RS 450 |

90 |

30 |

|

|

EW25-FS120 |

120 |

76 - 250 |

≤ 25 |

RS 350* |

120 |

120 |

|

120 |

251 - 350 |

≤ 25 |

RS 450* |

120 |

120 |

*For EW25-FS120 please note that the RS brackets should not penetrate the full width of the product and instead only extend 75% into the barrier width. For further information please refer to the installation instructions.

Please note:

- EW25-FS120 has only been tested in combination with 50mm thick stonewool thermal insulation (classified A1 to EN 13501-1) above and below the cavity barrier/firestop.

- Brackets are available in two forms: (G) denotes galvanised steel brackets and (S) denotes stainless steel brackets.

- RS Brackets must be installed at 400mm centres based on a 1200mm strip.

- For lengths ≤800mm 2no brackets must be used, with spacing reduced pro-rata.

- Lengths <100mm should be avoided by cutting down the adjacent barrier accordingly

- All brackets to be suitably fixed to substrate with non-combustible fixings.

- All brackets to penetrate product at mid-thickness.

- Please refer to separate installation instructions.

When considering Steel Frame Systems (SFS) the supporting substrate should be capable of providing support to the barrier for the required period of fire resistance.

For other void sizes or additional advice, please contact Technical Services.

Thermal conductivity: λ = 0.038 W/m.K ±5% (tested foil to foil) to EN 12667: 2001

Damp Proofing

Siderise EWI must be damp-proofed in accordance with PD6697:2019 - 'Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2'.

Siderise EWI - Cavity Barrier and Firestops

Table 2 : Product Properties

| Properties | Value |

|---|---|

| Reaction to fire |

The reactive intumescent along the leading edge is Class 'E' to EN 13501-1. This is permitted by Regulation 7(3)(f) - Approved Document B for England & Wales. |

| Resistance to fire |

Please see Table 1 |

| Thermal Conductivity |

λ = 0.038 W/m.K ±5% (tested foil to foil) to EN 12667: 2001 |

| Chemical Properties |

The base stone wool is chemically inert. An aqueous extract of the rock wool is neutral (pH7) or slightly alkaline. Resistant to most acids and weak alkaline solutions. |

| Biological Properties |

Vermin and root proof and does not encourage the growth of fungi, moulds, or bacteria. |

| Effect of Water |

Non-hygroscopic. Unaffected by humid atmosphere. Must be suitably damp proofed in accordance with codes of practice when used in masonry applications. |

| Compatibility |

Compatible with all normal building materials. |

| Maintenance |

No maintenance required unless disturbed. |

| Handling |

Easy to handle but should be treated with due care to ensure material integrity and shape are maintained. |

| Storage |

Store in dry conditions and protect from mechanical damage. |

Siderise offers a range of ancillary products to complement the EWI range these include:

- Fixing Brackets must be used in the installation of the product. Brackets come in two types: 'G' - Galvanised Steel Brackets and 'S' - Stainless Steel Brackets.

- Aluminium Jointing Tape must be used at all joints and intersections:

- RFT120/45 (120mm wide x 45m rolls)

- Adhesive backed

- Supplied in boxes of 8

Note – Tape should not overlap or impede the intumescent face of the EWI

- Stone wool core is recyclable.

The following information is available for download via the website:

- Standard Details

- NBS Specification Clauses

- Installation Instructions

- Safety Data Sheet

For technical advice or support please contact the technical team: technical.services@siderise.com

For Installation Training or Site Inspections please contact: site.services@siderise.com

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

FAQs

Get quick answers to common queries or contact our team for more advice. Your questions answered.

Yes, our site services engineers combine classroom learning with toolbox training and includes mock-up benchmark installations, free-of-charge.

In the event of a fire, the intumescent material in the product will activate at a critical temperature and expand in a matter of minutes until the gap is fully closed and a robust fire seal is formed, preventing the spread of fire, smoke and heat

Case Studies

Related projects

Siderise is a market leader in the design and development of specialist passive fire.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.