Siderise TW Cavity Barrier and Firestop for Tops of Walls

Cavity barriers and Firestops designed to ensure compartmentation at the tops of compartment walls

Continue compartmentation

TW Cavity Barrier and Firestop is designed for use within the joint between the top of compartment walls, partitions or fire-resistant suspended ceilings and the structural soffit. It features Lamella insulation comprising durable vertically oriented stone wool fibres which have been laterally pre-compressed under factory-controlled conditions and held with aluminium foil facings for reliable compartmentation and acoustic benefits.

TW Cavity Barrier and Firestop is available in a variety of size options to cover gap heights between 20 – 400 mm, all with EI 30 to 120 options in accordance to BS EN 1366-4:2006+A1:2010

The product provides tested acoustic performance with Weighted Sound Reduction Index values as low as 23 Rw (dB), helping to reduce room-to-room sound transmission

The flexibility of the Lamella insulation core and its compression fit means it can flex and recover in line with any building movement

Siderise firestops for tops of walls provide a seal between the top of the compartment wall, partition, or fire-resistant suspended ceiling, and the structural soffit. The choice of material is determined by the performance requirement in terms of fire resistance (i.e. insulation and integrity) and size of the cavity.

Uses include:

- Fire-stopping voids above compartment walls and partitions up to 600mm dependent on fire performance

- As an acoustic barrier at tops of walls

Siderise firestops for tops of walls comprise a single, close dimensioned product with a unique pre-compressed internal stone wool mineral fibre lamella core. The materials are manufactured using a unique manufacturing process to provide a resilient compression which ensures a tight fit. They are either supplied as pre-cut units to suit a quoted cavity size or in sheet form for cutting on site.

The range of Siderise firestops for tops of walls includes various types of products which are referenced ‘TW’ to designate the ‘Tops of Walls’ application. The materials have been developed and tested at various thicknesses to meet the fire and acoustic performance requirements listed in Tables 2 and 3, respectively.

Where TW spans from the top of a wall to a profiled deck the product can be profiled to follow the contours of the metal deck, ensuring a continuous and effective seal across varying geometries. This can be done onsite or provided by Siderise as a precut.

Where there is no gap between the top of the wall and the underside of a profiled deck, please refer to the TW-P product, which can be used to infill the discreet voids within the profile.

Siderise TW has been Third-Party tested and classified as A1 to EN 13501-1. Please see Table 1 for further information.

Table 1: Reaction to Fire Performance

| Properties | Value |

|---|---|

| Classification |

A1 to BS EN 13501-1: 2018 |

| Certificate No. |

WHI-09/02-22-000001-03 (UK) WHI20-32944302 (US) |

| Thickness Range |

50-175mm* |

| Substrates |

Mechanically fixed to gypsum or any other A1 or A2-s1, d0 substrate |

| Joints |

With or without joints |

*Please note that the thickness declared here refers to reaction to fire testing (supported by certificates - WHI-09/02-22-000001-03 (UK) & WHI20-32944302 (US)) carried out on the base material from which TW is manufactured and so covers a wider range than the thicknesses used for TW resistance to fire testing shown in Table 2.

The design and manufacture of Siderise TW is based on fire resistance testing in general accordance EN 1366-4:2006 + A1:2010.

Table 2 -Fire Resistance to EN 1366-4

| Product Ref | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Mins) | Insulation (mins) | Product Length (mm) | Bracket Requirement |

|---|---|---|---|---|---|---|---|

|

TW-CB30 |

20 - 50 |

75 |

+10% |

60 |

30 |

1200 |

No brackets** |

|

51 - 150 |

75 |

+10mm |

60 |

30 |

1200 |

2no.B65/110 600mm centres |

|

|

151 - 240 |

75 |

+10mm |

60 |

30 |

1200 |

2no.B195 600mm centres |

|

|

241 - 300 |

75 |

+10mm |

60 |

30 |

1200 |

2no.B355 600mm centres |

|

|

TW-FS60 |

20 - 50 |

90 |

+10% |

90 |

60 |

1200 |

No brackets** |

|

51 - 150 |

90 |

+10mm |

90 |

60 |

1200 |

2no.B65/110 600mm centres |

|

|

151 - 240 |

90 |

+10mm |

90 |

60 |

1200 |

2no.B195 600mm centres |

|

|

241 - 300 |

90 |

+10mm |

90 |

60 |

1200 |

2no.B355 600mm centres |

|

|

TW-FS120 |

20 - 50 |

120 |

+10% |

120 |

120 |

1200 |

No brackets** |

|

51 - 150 |

120 |

+10mm |

120 |

120 |

1200 |

2no.B65/110 600mm centres |

|

|

151 - 240 |

120 |

+10mm |

120 |

120 |

1200 |

2no.B195 600mm centres |

|

|

241 - 300 |

120 |

+10mm |

120 |

120 |

1200 |

2no.B355 600mm centres |

|

|

TW-CB30X |

301 - 400 |

90 |

+10mm |

60 |

30 |

1200 |

2no.B355 600mm centres |

|

TW-FS60X |

401 - 600 |

120 |

+20mm |

90 |

60 |

1200 |

2no.B355 600mm centres |

** Whilst some void widths of TW have been tested in general accordance with EN 1366-4 without mechanical fixings and brackets, we note that some supervising authorities may require a form of mechanical fixing. We recommend engaging with the project supervising authorities prior to installation to ensure all their requirements are met.

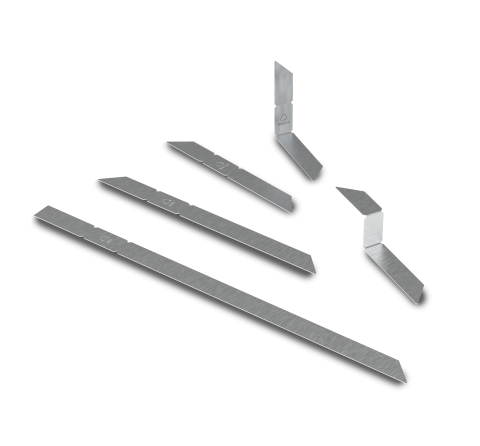

- Brackets must be installed at 600mm centres based on a 1200mm strip, This can be reduced pro rata for shorter lengths. Please note that a minimum of 2 brackets are required for any length of barrier greater than 250mm. For lengths ≤250mm a single bracket must be utilised.

- All brackets to be suitably fixed to substrate with non-combustible fixings

- All brackets to penetrate product at mid-thickness.

- All brackets to penetrate to a depth of 75% of gap width.

Siderise firestops for tops of walls can help to reduce room-to-room sound transmission. The installation of the products above a partition will contribute to room-to-room sound insulation performance. The achievable performance will depend on the construction of the wall and ceiling. Please contact our Technical Services department for further guidance around using this product.

Table 3 confirms the laboratory tested values for Weighted Sound Reduction Index (dB Rw) in accordance BS EN ISO 10140-2:2021; Acoustics-Laboratory measurement of sound insulation of building elements, Part 2: Measurement of airborne sound insulation.

Table 3 - Acoustic Performance (Weighted Sound Reduction Index)

| Product Type | Thickness (mm) | Rw (dB) | C:Ctr |

|---|---|---|---|

|

TW-CB30 |

75 |

21 |

(-1;-2) |

|

TW-CB30X |

90 |

21 |

(-1;-2) |

|

TW-FS60 |

90 |

21 |

(-1;-2) |

|

TW-FS60X |

120 |

23 |

(-1;-3) |

|

TW-FS120 |

120 |

23 |

(-1;-3) |

Rw is the weighted sound reduction index. It is a laboratory measured value to identify the airborne sound insulation performance of a building element. It is used for internal or external walls, ceilings/floors, windows, doors, or any separating element. The higher the Rw value, the better that element performs in reducing sound transmission.

Please note that the values presented in the above table refer to the standalone performance of the Siderise products only.

Thermal conductivity : λ = 0.038 W/m.K (tested foil to foil)

Siderise TW Firestops for Tops of Walls

Table 4: Product properties

| Properties | Value |

|---|---|

| Form supplied | Sheets 1200mm x 1200m x thickness, Cut strips 1200mm x cavity + compression x thickness, See Table 1 |

| Colour | Silver, with coloured identification tape centrally located on product |

| Finish | Aluminium foil |

| Density | Nominal 75 kg/m3 |

| Thermal conductivity | λ= 0.038 W/m.K (tested foil to foil) |

| Cavities | 20mm to 600mm |

| Reaction to Fire | Class ‘A1’ to EN 13501-1. Please see Table 1. |

| Resistance to Fire | 30 to 120 minutes (integrity/insulation). Please see Table 2. |

The stone wool core is recyclable

The following information is available upon request or via download from the website:

- Material Data Sheet

- NBS Specification Clause

For technical advice or support please contact: [email protected]

For Installation Training or Site Inspections please contact: [email protected]

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

FAQs

Get quick answers to common queries or contact our team for more advice. Your questions answered.

TW Cavity Barrier and Firestop can be supplied pre-cut or as a sheet for cutting onsite

It can achieve thermal conductivities of 0.038 W/m.K (tested foil to foil)

We can manufacture bespoke sizes of TW Cavity Barrier and Firestop to protect voids up to 1,200mm. Please contact our technical services team with your project details for more information

Case Studies

Related projects

Siderise is a market leader in the design and development of specialist passive fire.

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.