Published 15 Jan 2024

What is lamella and why is it ideal for passive fire protection?

What is lamella and why is it ideal for passive fire protection?

There are several types of cavity barriers and firestops for different kinds of façades available on the market. However, for all applications, it is vital that these firestopping products not only deliver the fire resistance necessary to ensure compartmentation, but also that they can achieve and maintain good form and fit for the lifetime of a system, even when subjected to building movement.

In 1991, Siderise created Lamella to ensure just that.

Context

Traditional cavity barriers and firestops are typically made using non-combustible stone wool insulation with horizontal fibres. This makes the products stable but difficult to repeatedly compress. This can result in a breakdown of bonding between the fibres and the product will not recover/flex in line with how the façade is moving, resulting in a gap forming between the product and the façade and causing the firestopping to fail.

They also require a ‘wet’ install, where installers must cut and compress the insulation material onsite and then seal it with a sprayed-on compound. This means it was difficult for installers to ensure consistent compression across the construction and, once the compound is applied, the only way to check if the right compression has been achieved is through destructive testing.

Recognising the limitations of these standard spray on fire seals and horizontally fibered fire barriers— and understanding the need for reliable fire safe constructions— we engineered an innovative dry-fit stonewool Lamella solution with a patented HSL manufacturing process.

A safer approach

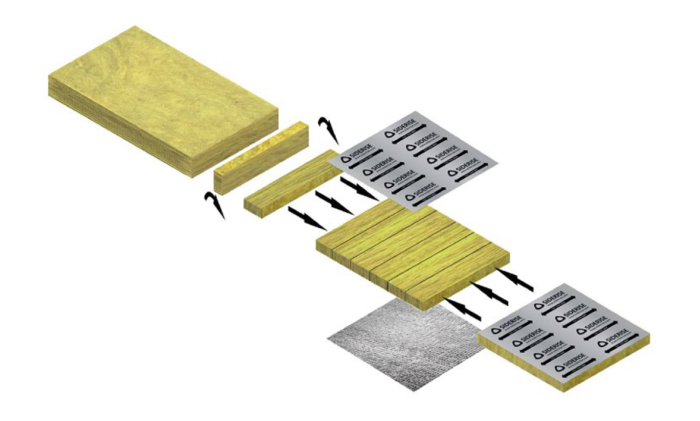

Lamella features stonewool insulation with vertically oriented fibres which are laterally compressed under quality-controlled factory conditions to remove any gaps between the sections and fibres which may cause weakness. This ‘pre-compression’ is held in place by heat-applying a foil facing, which also provides weather protection without the need for a wet sealant.

When exposed to fire, the foil facing is designed to delaminate from the product which releases the factory-induced pre-compression. This allows the product to expand and ensures integrity is maintained, even under the greater building movement caused by the fire load.

Extensive age testing of Lamella products has shown that this vertical fibre structure allows them to be repeatedly compressed with no loss of recovery/flex, meaning that the integrity of seal between the façade and floor slab is constantly maintained throughout the lifetime of the building. The result is a structurally-sound, fire-safe solution that is simpler and quicker to install.

Lamella now features in many of our passive fire protection and acoustic product ranges and has been used on projects around the world. Explore our products or check out our project case studies to learn more.