Siderise RF Cavity Barrier and Firestop for Raised Access Floors

Compartmentation solutions for preventing fire spread under raised access floors

Safety right under your feet

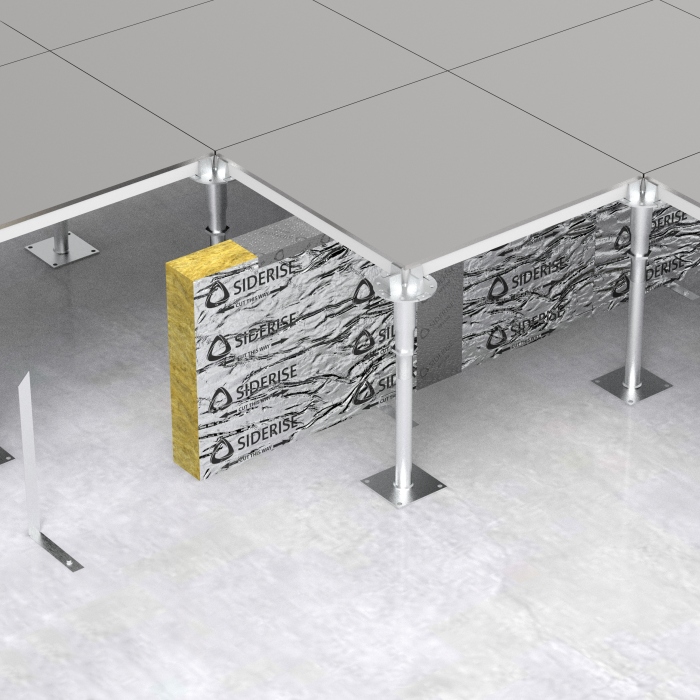

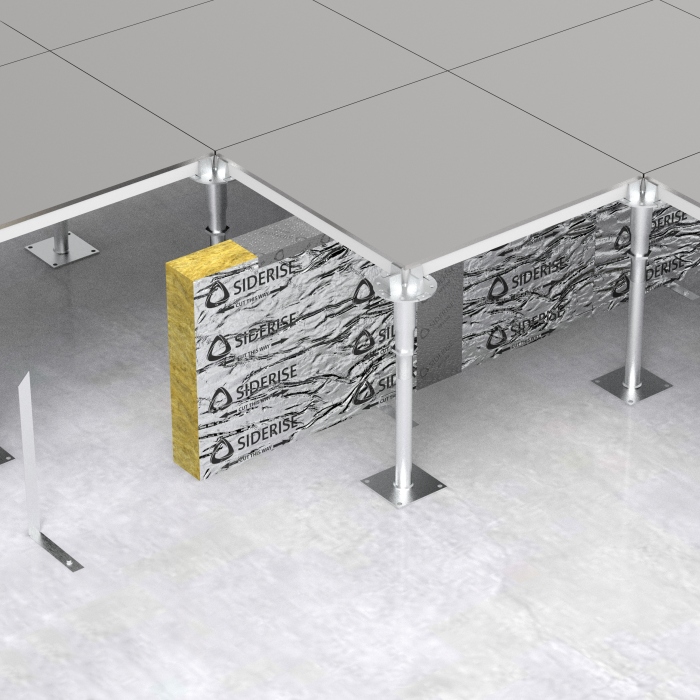

RF Cavity Barrier and Firestop is a block of Lamella featuring a stone wool core with vertically oriented fibres laterally compressed and held in place by a foil facing. It has been designed and tested to resist the spread of fire, smoke and heat in the unseen void between the floor slab and a raised access floor. It can either be used to subdivide large uninterrupted voids, or to provide continuity of fire resistance when aligned underneath internal walls.

RF Cavity Barrier and Firestop has been tested to EN 1366-4 for up to 120 minutes fire resistance (integrity and insulation)

RF Cavity Barrier and Firestop can reduce room-to-room sound transmission, improving privacy and preventing disturbance from neighbouring rooms

RF Cavity Barrier is suitable for use in void heights up to 600mm. RF Firestop is suitable for use in voids up to 1000mm. Both are suitable in air plenum applications

Siderise RF Cavity Barrier & Firestop Systems prevent the spread of fire and smoke, and reduce sound transmission, by sealing the voids between raised access floors and floor slabs.

The range includes options to either subdivide large uninterrupted cavities (Cavity Barriers) or to provide continuity of fire resistance when aligned underneath partitions (Fire Stops). Across the range, these simple to install systems have been tested for fire performance, acoustic performance and for use as a plenum liner.

Siderise RF-CB Cavity Barrier systems are used to subdivide uninterrupted voids in accordance with Building Regulations and offer 30 minutes of fire resistance. Please see Table 2 for ratings by void size.

Siderise RF-FS Firestop systems maintain continuity of fire resistance for installations aligned with fire-rated partitions hence maintaining compartmentation. The 'FS' systems offer 60 to 120 minutes of fire resistance.

RF-FS barriers are designed to suit individual floor void depths. They are a one-piece system that affords easy cutting and installation. Additionally, due to a unique manufacturing process, the products offer unique vertical compression to allow tightness of fit.

Siderise RF Cavity Barrier & Firestop Systems have been tested in general accordance with EN1366-4. Please refer to Table 2 for details.

Siderise RF Cavity Barrier & Firestop Systems are classified A1 to EN 13501-1 and comprise a unique non-combustible stone wool lamella core, which is faced on two sides with an impervious aluminium foil, offering excellent resistance to the passage of smoke.

Siderise RF is available in the following forms:

Pre-cut Strips

• Pre-cut products are available in 1mm increments of width to suit the cavity size. Please see Table 1 regarding 'fit type'.

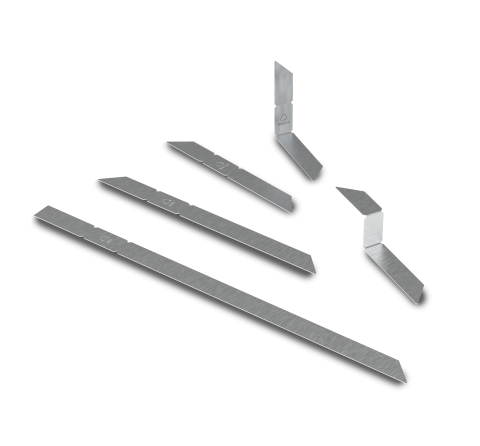

• Supplied with appropriate brackets as part of a system.

Sheets

• Standard sheet size is 1200 x 1200mm and may be of benefit when the actual void size is not known or where it varies significantly.

• Appropriate brackets must be ordered separately.

In terms of 'Reaction to Fire', the products are classified 'A1' to EN 13501-1. See Table 1.

Table 1 : Reaction to Fire Performance

| Properties | Value |

|---|---|

| Classification |

A1 to EN 13501-1 |

| Certificate No. |

WHI20-32944302 (US) WHI-09/02-22-000001-03 (UK) |

| Thickness Range |

50-175mm* |

| Substrates |

Mechanically fixed to gypsum or any other A1 or A2-s1, d0 substrate |

| Joints |

With or without joints |

Siderise RF cavity barrier and fire stop systems have been successfully tested to EN 1366-4 for up to 120 minutes fire resistance (integrity and insulation). See Table 2.

Table 2 : Resistance to Fire to EN 1366-4

| Product Ref | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Mins) | Insulation (mins) | Product Length (mm) | Bracket Requirement |

|---|---|---|---|---|---|---|---|

|

RF-CB30 |

50 - 200 |

75 |

+10mm |

60 |

30 |

1200 |

2no.B195 600mm centres |

|

RF-FS60 |

50 - 200 |

90 |

+5mm |

60 |

60 |

1200 |

No brackets** |

|

RF-FS120 |

50 - 200 |

120 |

+10mm |

120 |

120 |

1200 |

2no.B195 600mm centres |

|

RF-CB30 |

201 - 300 |

75 |

+10mm |

60 |

30 |

1200 |

2no.B195 600mm centres |

|

RF-FS60 |

201 - 300 |

90 |

+10mm |

90 |

60 |

1200 |

2no.B195 600mm centres |

|

RF-FS120 |

201 - 300 |

120 |

+10mm |

120 |

120 |

1200 |

2no.B195 600mm centres |

|

RF-CB30-X |

301 - 400 |

90 |

+10mm |

60 |

30 |

1200 |

2no.B355 600mm centres |

|

RF-FS60-X |

301 - 400 |

120 |

+20mm |

60 |

60 |

1200 |

2no.B355 600mm centres |

|

RF-FS60-X |

401 - 600 |

120 |

+20mm |

60 |

60 |

1200 |

2no.B355 600mm centres |

|

RF-FS60-X |

601 - 1000 |

120 |

+40mm |

60 |

60 |

1200 |

4no. B355(300mm centres) |

NOTE - To facilitate the required compression, raised access floor panels will require mechanical fixing to the floor pedestals. This is to ensure that the panels are correctly seated onto the pedestals whilst providing the required compression to the RF.

** Whilst RF-FS60 has been tested in general accordance with EN 1366-4 in void widths 50-200mm without mechanical fixings and brackets, we note that some supervising authorities may require a form of mechanical fixing. We recommend engaging with the project supervising authorities prior to installation to ensure all their requirements are met.

- Brackets must be installed at 600mm centres based on a 1200mm strip, except for between 601-1000mm voids which should be installed at 300mm centres. This can be reduced pro rata for shorter lengths. Please note that a minimum of 2 brackets are required for any length of barrier greater than 250mm. For lengths ≤250mm a single bracket must be utilised.

- All brackets to be suitably fixed to substrate with non-combustible fixings

- All brackets to penetrate product at mid-thickness.

- All brackets to penetrate to a depth of 75% of gap width. For RF-FS60-X used in voids of 601-1000mm, brackets should penetrate 355mm.

- Please refer to the installation instructions for further details.

Joint Type

- Butt Joint (RF-CB-BJ and RF-FS-BJ) available as standard.

- Rebate Joint (RF-CB-RJ and RF-FS-RJ) available on request. For rebate joints cover length is 1175mm.

- Please advise joint style at time of ordering.

The installation of Siderise RF cavity barrier and fire stop systems can enhance the ‘room-to room’ sound reduction of raised access floors which form a continuous common void under adjacent areas. This can result in improved speech privacy and greater control of disturbance from intrusive noise.

The acoustic performance of the RF material is due to the unique internal construction of the stone wool lamella core. The product’s foil facings and the additional sealing of the vertical joints with foil tape all serve to provide improved air tightness.

The product’s standalone acoustic performance is tested in accordance with BS EN ISO 140-3:1995. Weighted sound reduction index (dB Rw) values for various grades of the product are given below in Table 3.

The acoustic flanking performance of a raised access floor (given as a dB Dn,f,w value) will be affected by both the floor tiles themselves and any cavity barriers which may be installed in the void. The below values represent the performance of Siderise RF barriers only.

Table 3 - Acoustic Performance (Weighted Sound Reduction Index)

| Product Type | Thickness (mm) | Rw (dB) |

|---|---|---|

|

RF-CB30 |

75 |

21 |

|

RF-CB30-X |

90 |

23 |

|

RF-FS60 |

90 |

23 |

|

RF-FS60-X |

120 |

25 |

|

RF-FS120 |

120 |

25 |

Thermal conductivity : λ = 0.038 W/m.K (tested foil to foil)

Siderise RF Cavity Barrier and Fire Stop systems

Table 4 : Product Properties

| Properties | Value |

|---|---|

| Form supplied | Sheet BJ: 1200mm x 1200mm x thickness, Sheet RJ: 1200mm x 1175mm x thickness, Pre-cut strips: 1200mm x (cavity + compression) x thickness (See Table 2) |

| Colour | Silver |

| Finish | Bright aluminium foil |

| Density | Nominal 75kg/m3 |

| Thermal conductivity | λ= 0.038 W/m.K (tested Foil to Foil) |

| Cavities | 50mm to 1000mm |

| Fire resistance | 60-120 mins (Integrity) & 30-120 mins (Insulation) see Table 2 |

| Reaction to fire | Class ‘A1’ to EN 13501-1 see Table 1 |

The stone wool core is recyclable.

The following information is available upon request or via download from the website:

- NBS Specification Clause

- Installation Instructions

- Safety Data Sheet

For technical advice or support please contact: technical.services@siderise.com

For Installation Training or Site Inspections please contact: site.services@siderise.com

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

FAQs

Get quick answers to common queries or contact our team for more advice. Your questions answered.

It can either be supplied as pre-cut strips available in 1mm increments of width to suit the cavity size or in a standard 1200 x 1200 mm sheet to be cut onsite

The product has been designed as a one-piece system for easy cutting and installation within raised access floor systems

The appropriately sized brackets will be supplied with pre-cut strips as standard. Where the product is being cut onsite, brackets will need to be ordered separately to match your requirements

Contact us

We're here to help you

Call for our main switchboard

Email us for technical enquiries

Email us for site support

Complete the form for the right response

Augmented Reality

Point your camera at the QR code. Tap the banner that appears on your screen.